Have you ever heard about Tie-in Point? It is a wide and important subject to process design that I learned only after College.

In a few words, the tie-in point is a future connection to an existing process. That means that exists an industrial plant in operation and to “add” a new process it is necessary to build a physical connection between them.

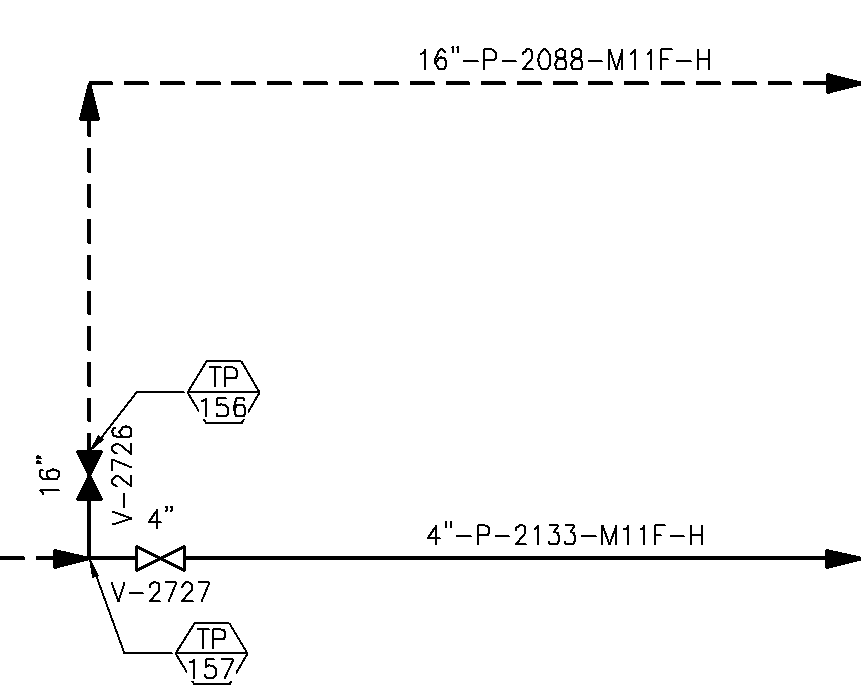

The tie-in point is shown in the P&ID and in the isometrics, however, it is important to have a Tie-in Point List in order to make easier plant interface management among design, construction and operation team.

As a chemical process engineer, you will be involved with tie-in point definition related to the piping system. For instance, where it should or should not be located, what kind of hazards can be added to the process, which system needs to be isolated, operational procedure or manual review etc.

Tie-in point should be defined with Operation and Maintenance knowledge because of, usually, the process plant needs to be shutdown, stopping production.

In some cases, future points of connections defined during the design phase of a project can avoid this kind of problem. An alternative to do a tie point during plant operation is to evaluate the risks of hot tapping.

Hot Tapping

Hot Tapping is the ability to safely tie into a pressurized system, by drilling or cutting, while it is on stream and under pressure. Hot tapping is used in order to repair areas that have undergone mechanical damage or corrosion, or to add branches for system modifications.

Be aware that hot tap is not a routine procedure, it shall be used only when there is no practical alternative.

In the piping system a machine is started and cuts until the cutter passes through the pipe wall, resulting in the removal of a section of pipe.

To perform a hot tapping, as a chemical process engineer, you will need to inform design and operational info like flow, pressure and temperature. Be part of managing of changes, hazard analysis etc.

Some other info related to hot tapping is pipe nominal size, wall thickness, length, flange/interface specification, clearance space for hot tapping machine etc.

The use of block valve requires a full bore size one, for instance, ball or gate type.

You can learn more about chemical process engineering and plant design subscribing to my social media at www.jefersoncosta.com.