Although there are some methods available to remove water from a natural gas application, in a pre-selection we decided to use desiccant dehydration with regeneration process.

As a chemical process engineer you need to inform supplier the feed gas specification (composition, pressure, temperature and flow) and the treated gas specification, for instance, gas dew point, maximum pressure drop, other contaminants specification if needed.

In general terms, natural gas must be dehydrated to remove water vapor. Water vapor causes the formation of hydrates, over saturation of natural gas and corrosion of equipment. Another reason is to comply with Customer specifications.

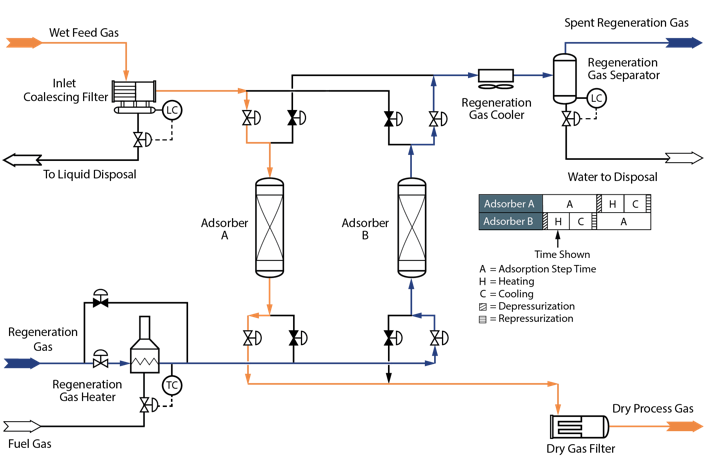

In this process, water is removed from gas using adsorption dehydration units. While one vessel is on stream the other one is in regeneration mode using part of the dry gas, heating and cooling. During regeneration hot gas passes through a molecular sieve to remove the water, the hot gas is then cooldown to remove water by condensation and the gas is recycled to the process to prevent gas emission.