Ingress Protection is something chemical process engineers usually do not worry about. However, in small companies, we may need to use different hats to do our job. For that reason, it is interesting to know what IP means and how to use that.

Ingress protection (IP) is used to specify the extent of protection an electrical/electronic enclosure has against environmental conditions. Electrical equipment (motor for instance) or an electronic instrument (a transmitter for example) installed in the field or in a building may need different levels of IP for the same process.

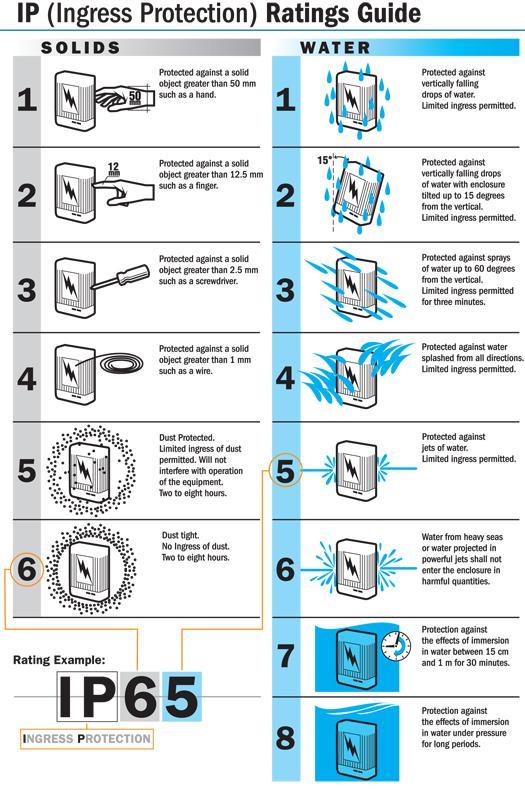

In fact, what really matters for IP specification is protection against dust/particles and against water. Depending on the amount of dust and water, it can damage an electrical or electronic circuit. To prevent that the International Electromechanical Commission (IEC) developed a system to classify enclosures and compare levels of sealing (IEC PUBLICATION 529). IP is defined by two algorisms, the first one take into account dust/particles and the second one water. The meaning of each number is in the picture below.

To deal with IP specification we need to know about the plant layout, equipment/instrument location and about the process.