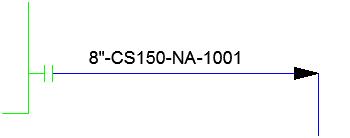

10”-HC-22A-025-Bc-PP.

My home, my rules. What I am talking about?

The piping and instrumentation diagram (P&ID) has info available for process design. Understand what each number and letter mean in this drawing save time and give you a map of the process.

Reading pipe identification is one of the most basic skills chemical process engineers must have to work in an environment process (operations or design). Be aware that pipe identification depends on the Company´s standard. In a new job, always consult those documents before getting any conclusion.

It is very common to use the expression “line” to talk about a “pipe“. For instance, the Line list refers to a list with all pipes identification, a subject for another post.

In the 10”-HC-22A-025-Bc-PP example:

10″ – pipe nominal diameter (NPS)

HC – fluid identification 2

2A – process area

025 – line number

Bc – pipe specification

PP – insulation

Once you understand that, you can predict line identification in the drawings of other companies.

We can predict that 8″-CS150-NA-1001 is a 8” pipe size, made with carbon steel, fittings 150#, fluid? and line number 1001 or area 10 and line number 01. See that to confirm some info we need the Company´s standard or guideline.