Chemical Process Engineer deals with the conversion of raw materials into products using physical process, chemical reaction or both of them. As Process Engineer you SHALL need to understand each hazard you have in your process.

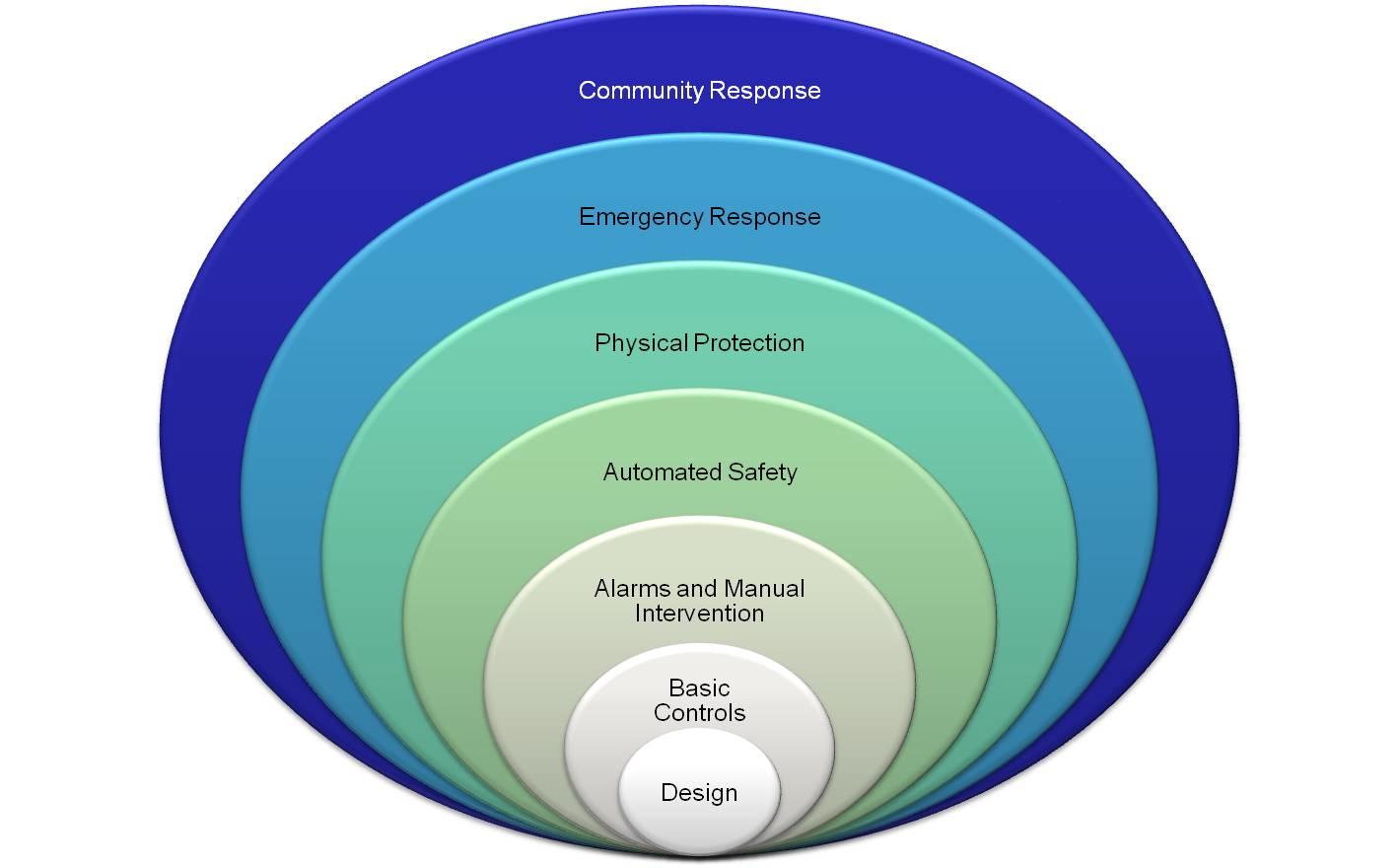

It does not matter if you work supporting Operations or in a Project Office we are responsible to evaluate and propose ways to reduce process hazards and/or risks.

The first step is to know the Material Safety Data Sheet (MSDS) related to the material used and produced in your process. You will find information like physical and chemical properties, stability and reactivity, exposure control/personal protection etc.

The second step is to evaluate the process. There are many methods: HazOp, HazId, LOPA to name a few. During the process safety review, it is very important to have meetings with the team to share experiences. If you are in an existing Plant listen carefully to Operators because they have a lot to share about day to day operations.

Keep in mind that Pressure, Temperature and Composition can stress piping and equipment leading to a failure, a failure can result in an accident and an accident can kill People and Companies.