That is a trick question and the first answer should be: It depends on.

First, as a Chemical Process Engineer, you need to know that in general terms there are two kinds of pumps: dynamics and positive displacement type.

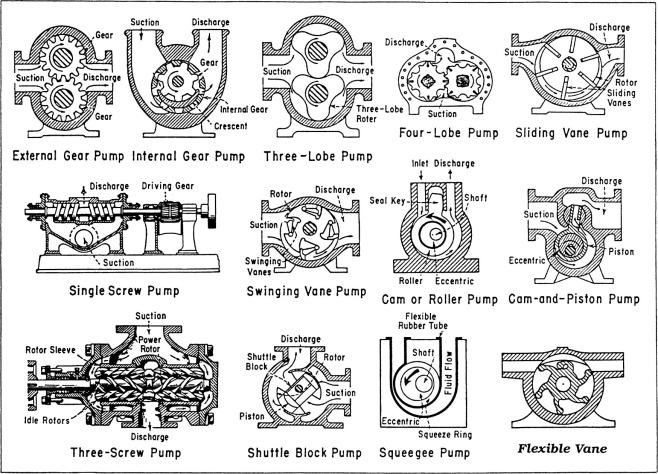

A positive displacement pump moves a fluid by repeatedly enclosing a fixed volume and moving it mechanically through the system. The pumping action is cyclic and can be driven by pistons, screws, gears, rollers, diaphragms or vanes. As the pump is always adding volume to the system they can build pressure up to failure if its discharge is blocked and there is no recirculation option.

Just to mention do not start a positive displacement pump with its discharge closed.

Backpressure is given by the system. In the other hand, maximum building pressure is based on pump mechanics, pipe, fitting, instruments and equipment maximum allowable working pressure (MAWP)

For those reasons you may be noted that a positive displacement pump always need a pressure safety device at its discharge. That pressure safety device can be a pressure safety valve (PSV) but in some cases can be a rupture disc, for instance. It is your task to understand what best fits your process.