Control valves are a constant in the life of a chemical engineer. As industrial plants get more and more automated, more control valves there are in the field. Thinking about chemical process engineering and plant design, the responsibility of control valve sizing may change from a company to another. I have seen companies where the chemical process engineer specifies the control valve, while in others, the chemical process engineer only fills a sheet with process data. In any case, as a chemical process engineer will be involved with control valves in any case.

Let me alert you that the control valve bibliography by itself is very extensive. It is not my intention to cover that here. Below I will share my experience as a chemical process engineer with expertise in plant design and point out some issues I believe you should care about.

CONTROL VALVES

To begin with, control valves are manual valves that have an automatic actuation, i. e., there is no need for an operator to regulate their opening. During their operation, it is expected that the valve regulates its opening within a range in other to keep the desirable variable under control. A clue to know which variable is controlled is to look at the control valve tag. For instance, a PV is meant to control pressure, an FV for controlling the flow, TV for controlling the temperature and etc. To know more about valve tags and identification take a look at the video P&ID Reading Revealed.

Control valves are different from than isolation valve, although the isolation valve may be automatically actuated, their open position is only open or close, or in other words, 0% or 100%. The control valve in another way is designed to operate around a 50% opening.

FLOW COEFFICIENT (Cv)

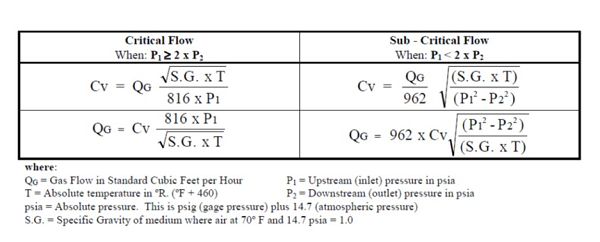

The nightmare of many students during chemical engineering course, the Cv is a constant related to the geometry of a valve, for a given travel, that can be used to establish flow capacity. It is the number of U.S. gallons per minute of 16°C (60°F) water that will flow through a valve with a one pound per square inch pressure drop. Although it is originally designed for liquid, there is also a Cv equation for gases. In this case, the formula becomes more intricate for gases, as gases are compressible fluids and are thus affected by temperature. Furthermore, two formulas are required to accurately estimate the flow. When the upstream pressure equals or exceeds two times the downstream pressure, it is known as a “choked flow” situation.

Cv Equation for Gases

Besides the traditional way to calculate Cv, ISA–75.01. 01-2007 includes equations for predicting the flow coefficient of compressible and incompressible fluids through control valves. ANSI/ISA s=Stadards S75.1 is harmonized with IEC Standards 534-2-1 (Incompressible fluids) and 534-2-2 (Compressible fluids). If you wanna go deeper in the Cv calculation look for those references.

In my years as a chemical process engineer, I used Cv calculation to evaluate some manual valves. I never used Cv calculation for sizing control valves and I recommend you do not do that either unless you work in a control valve supplier.

CONTROL VALVE DATASHEET

What a chemical process engineer working with plant design must know about control valve sizing, in my point of view, is which process data is needed for control valve calculation and how to fill correctly a control valve datasheet. With that, you or the person responsible for the valve selection will be able to use the supplier software to pre-select the best control valve to your process and service. To fill correctly a control valve datasheet besides knowing about process condition and control valve service, you should know about P&ID reading, ingress protection, area classification, and valve safe fail position at a minimum. In the video below, I show you a step by step of how to fill a control valve datasheet with clarification of some important points that you should take care of.

PS. It is not my intention to exhaust control valve sizing in this post. But let you, chemical process engineer, familiar with control valve sizing. And with that, increase your technical skills.

To download the editable version of the spreadsheet I use in the tutorial, just help the video reach 100 likes on YouTube. Besides that, join my Telegram Channel INPROCESS clicking in the link to my website.

To have more about chemical process engineering and plant design connect with me and also subscribe to my newsletter.

Website: https://www.jefersoncosta.com

My Blog: https://www.jefersoncosta.com/blog

Linkedin: https://www.linkedin.com/in/jeferson-costa-process-engineer

Facebook: https://www.facebook.com/inprocessbooster

YouTube: The Chemical Process Engineer and Plant Design

REFERENCES:

Emerson Fisher, CONTROL VALVE HANDBOOK, 5th ed

ISA-75.01.01-2007 Flow Equations for Sizing Control Valves