As Chemical Process Engineer you need to be familiar with control valves function and design.

To develop a process design you need to know which process data needs to be informed to Instrumentation Engineer or in other cases directly to Instrumentation Designer. Required process data depends on the kind of service is required by the control valve. Some types of services are control or on-off, if the fluid is liquid, gas or mixed etc.

Although Chemical Process Engineer is not familiar with some information like trim, positioner, switcher and so on in some companies you may be requested to verify supplier ISA sheet before purchasing, especially in small companies.

If you work in an Industrial Plant supporting Operations, you need to know how to evaluate an existing auto valve also. in many cases, in the day to day operation, process parameters change from its original design and evaluating a control valve can be the key to your Six Sigma project.

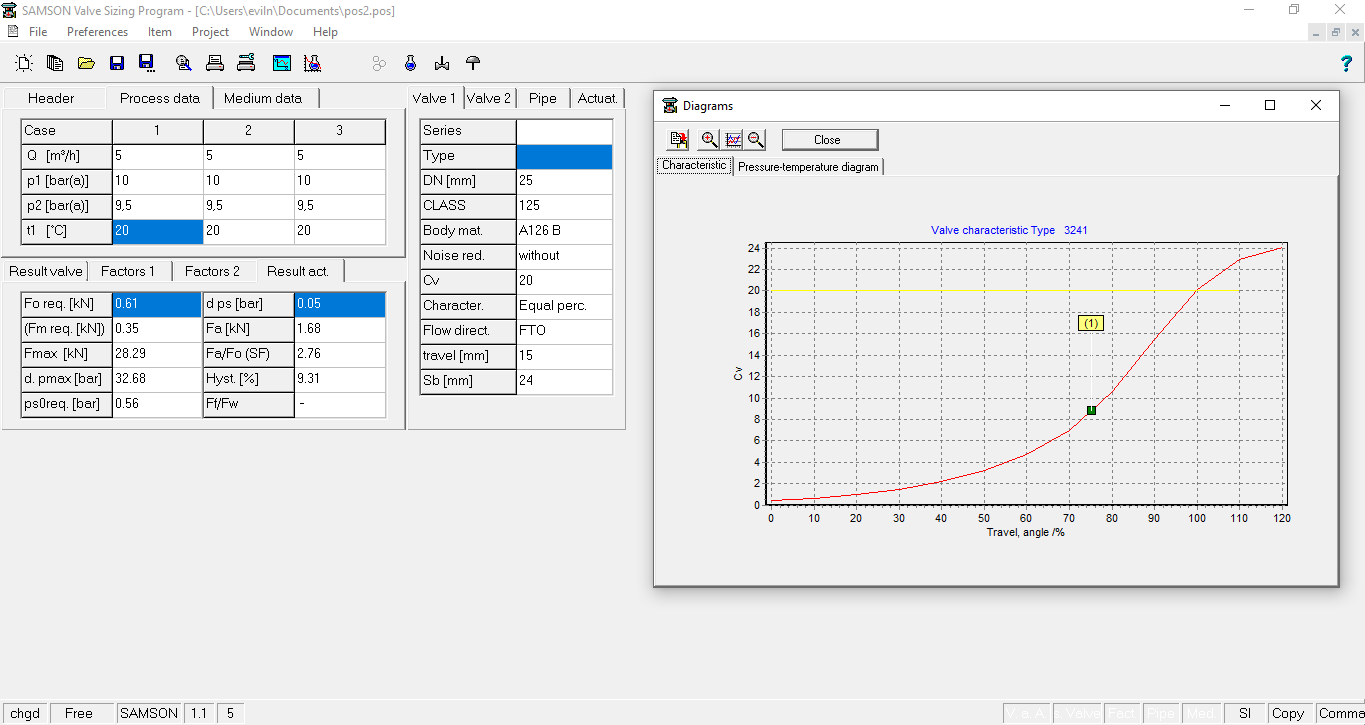

I recommend you to verify if the valve supplier of your plant has some design tool. Using that properly, you can predict valve size in a small project and evaluate the current operation, for instance.

In the picture, you can see Samson Valve Sizing Program 4.70 screen.

Subscribe to my social media at www.jefersoncsota.com to learn more about chemical process engineering and plant design.