Although it seems a dumb subject, the main objective of this article is to show you how to build a technical argument. In your career, people will question your work eventually. In order to not get embarrassed with your answer, read carefully to these works. I do not intend to solve the discussion between...

CONTINUE READINGMetal Design Minimum Temperature

And if I do not know what MDMT is? As chemical process engineers, you need to understand some definition to keep our process in a safe condition. MDMT is an acronym to Metal Design Minimum Temperature and mean the lowest permissible metal temperature for a given material at a specified thickness based on its...

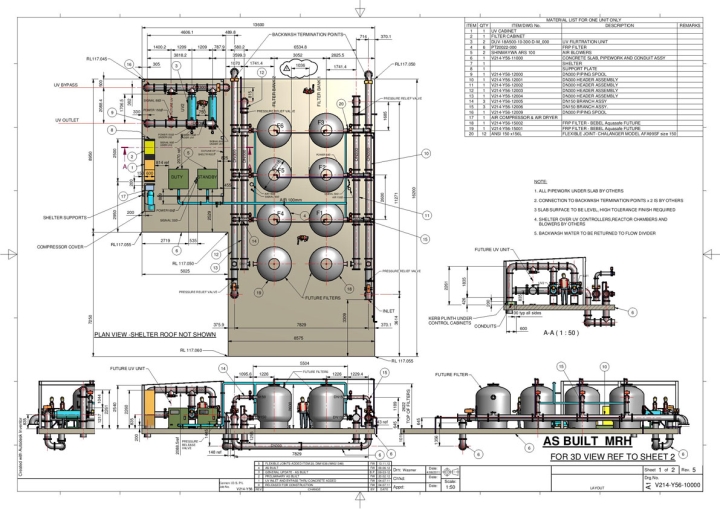

CONTINUE READINGChemical Process Engineer Interface With Plant Layout

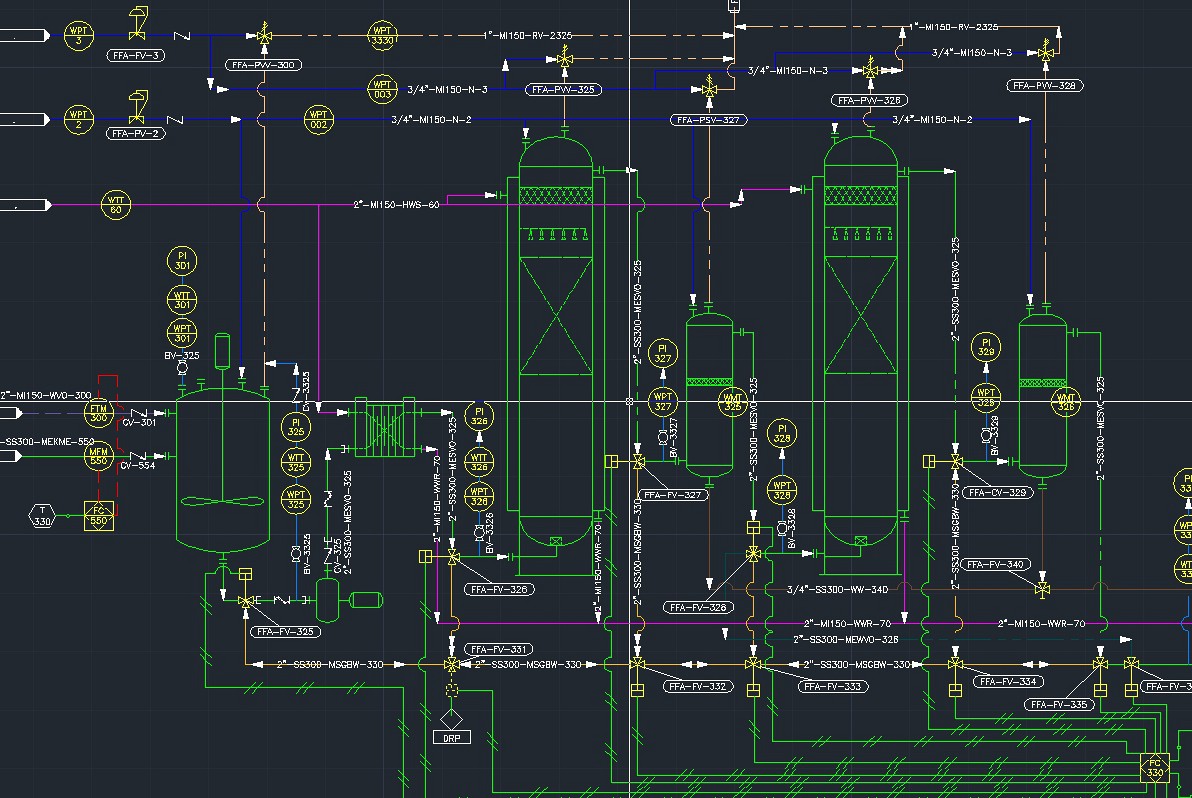

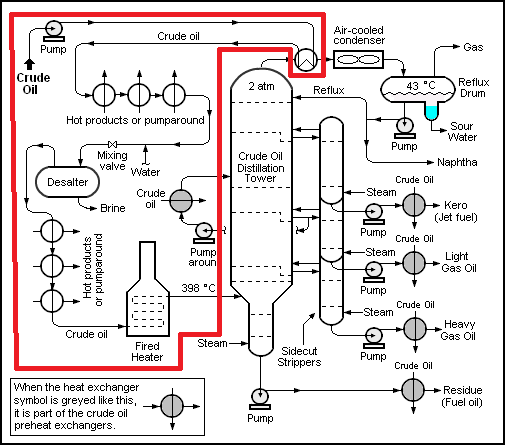

During the initial phase of a project, you will develop or be involved with at least three documents; process flow diagram (PFD), piping and instrumentation diagram (P&ID) and Plant Layout. Process Flow Diagram is a deliverable developed by the chemical process engineer. It is the representation of heat and material balance in a drawing....

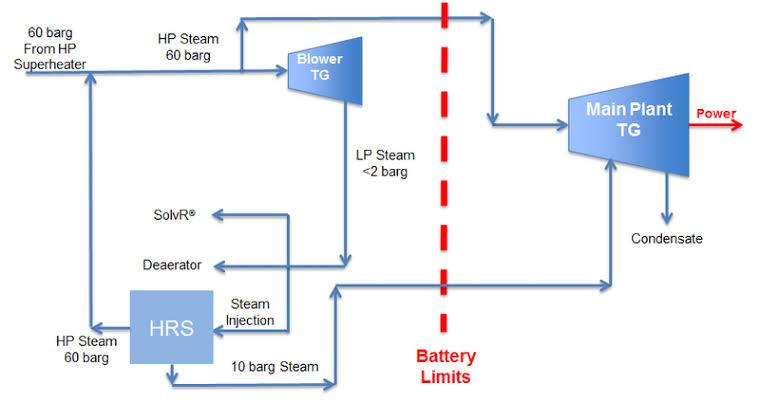

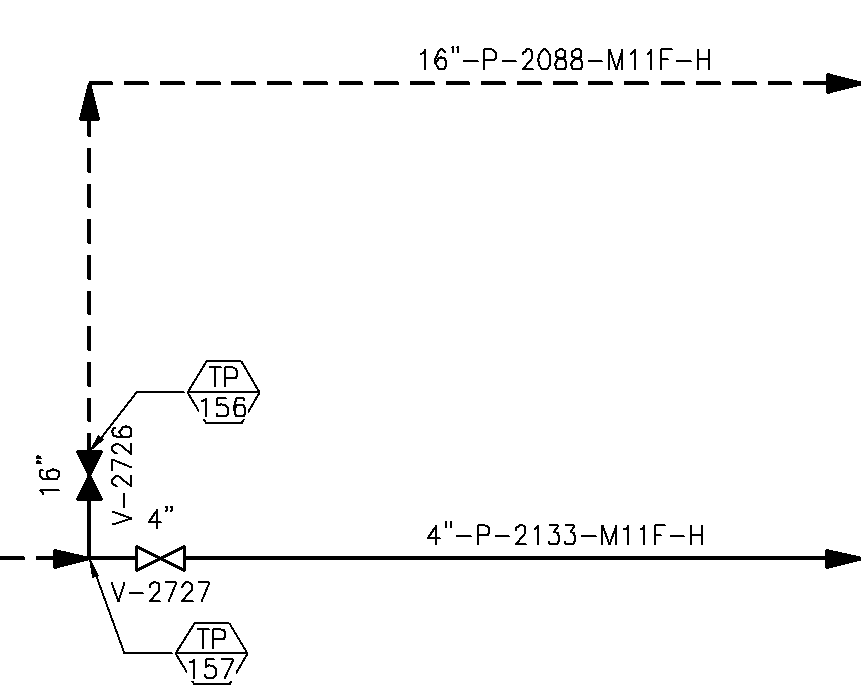

CONTINUE READINGWhat is battery limits and pressure drop calculation

With fluid data and knowing how to use equations, pressure drop calculation is not a big deal. However, be aware of the plant battery limit and contract of supply. Battery limits (BL) is the interface where responsibility goes to another hand. For instance, once the postman lets the letter at the mailbox, his/her responsibility...

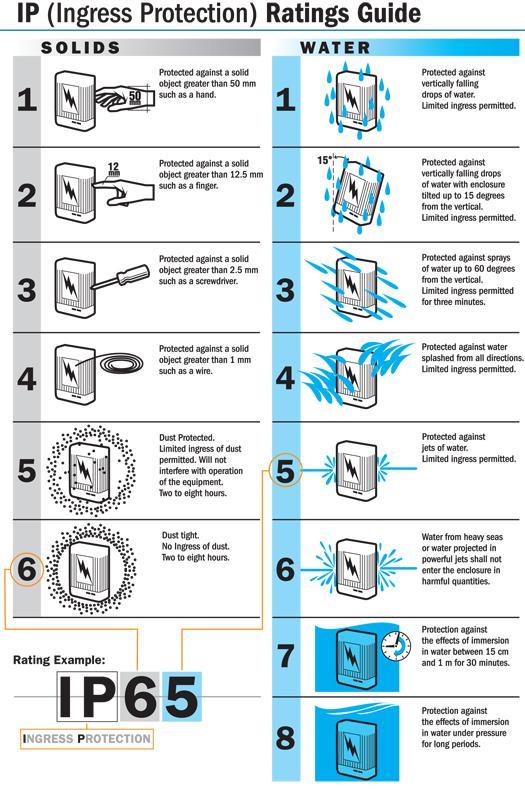

CONTINUE READINGIngress Protection (IP)

Ingress Protection is something chemical process engineers usually do not worry about. However, in small companies, we may need to use different hats to do our job. For that reason, it is interesting to know what IP means and how to use that. Ingress protection (IP) is used to specify the extent of protection...

CONTINUE READINGOperating Unit and Operating Process: what should you know?

In our role as a chemical process engineer, we need to follow up on raw material into products. How it takes will depend on a bunch of assumptions. In any case, to that come true, an industrial plant will have operating units, operation process or a mix of them. A simple way to differentiate...

CONTINUE READINGWhat is Standard and Normal flow?

Regularly gases are measured based on its volume per hour and there are some types of devices to do it. Usually, measurement units in these cases are SCFH and Nm3/h. Most processes are designed and set based on these units. As a chemical process engineer, you need to make surge that those measurement units...

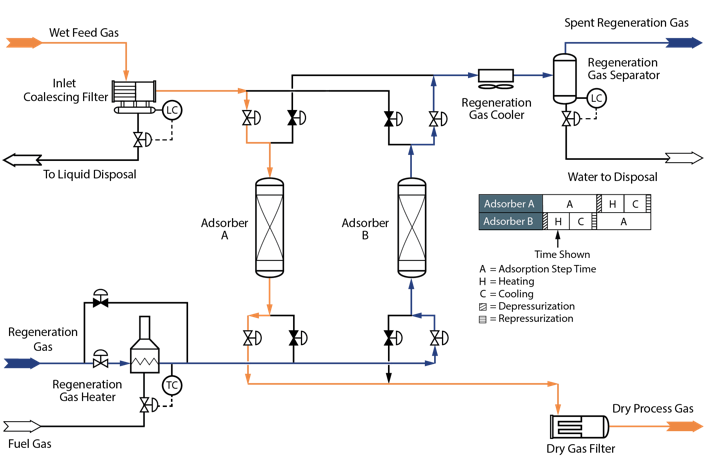

CONTINUE READINGGas Dissicant Dehydration

Although there are some methods available to remove water from a natural gas application, in a pre-selection we decided to use desiccant dehydration with regeneration process. As a chemical process engineer you need to inform supplier the feed gas specification (composition, pressure, temperature and flow) and the treated gas specification, for instance, gas dew...

CONTINUE READINGHot Tapping, what is this?

Today let´s talk about hot tapping. Hot Tapping is the ability to safely tie into a pressurized system, by drilling or cutting, while it is on stream and under pressure. Hot tapping is used in order to repair areas that have undergone mechanical damage or corrosion or to add branches for system modifications. Be...

CONTINUE READINGTie In Point

Have you ever heard about Tie-in Point? It is a wide and important subject to process design that I learned only after College. In a few words, the tie-in point is a future connection to an existing process. That means that exists an industrial plant in operation and to “add” a new process it is...

CONTINUE READING