Although it seems a dumb subject, the main objective of this article is to show you how to build a technical argument. In your career, people will question your work eventually. In order to not get embarrassed with your answer, read carefully to these works. I do not intend to solve the discussion between Piping and Process, as it seems to be a religious, soccer or political discussion.

Before starting, let me tell you that there is something called Kelsen’s Pyramid. Very know by Lawyers this theory talks about the hierarchy of rules. The legal system relies on it (I cannot tell if it applies to every place in the world, but I am pretty sure that the Americas and Europe were built this way). To not turn it too complicated, you just need to know that National laws precede Regional, which precedes Local rules. Besides that, countries assigned international rules at their own convenience.

In Plant design is not different, people need to comply with Laws in general, National Standards, International Standards, Company’s Procedures, Best Practice etc. If there is a conflict among them, you need to comply with that of higher hierarchy or most common, comply with the most restrictive one. Keep in mind that not complying with these “rules”, in many cases, may put you and others at risk.

Based on the above, the more reliable definition of P&ID would be taken from the regulation of your country. If there is no definition for that, you will need to rely on international standards. Companies’ procedures are based on National or International standards, eventually based on their own experience. Take this into consideration when complying with assessment requirements.

Now, let’s check some P&ID definitions:

The International Organization for Standardization – ISO 10628-1

Diagrams for the chemical and petrochemical industry — Part 1: Specification of diagrams

4.4 Piping and instrumentation diagrams (P&ID)

4.4.1 General

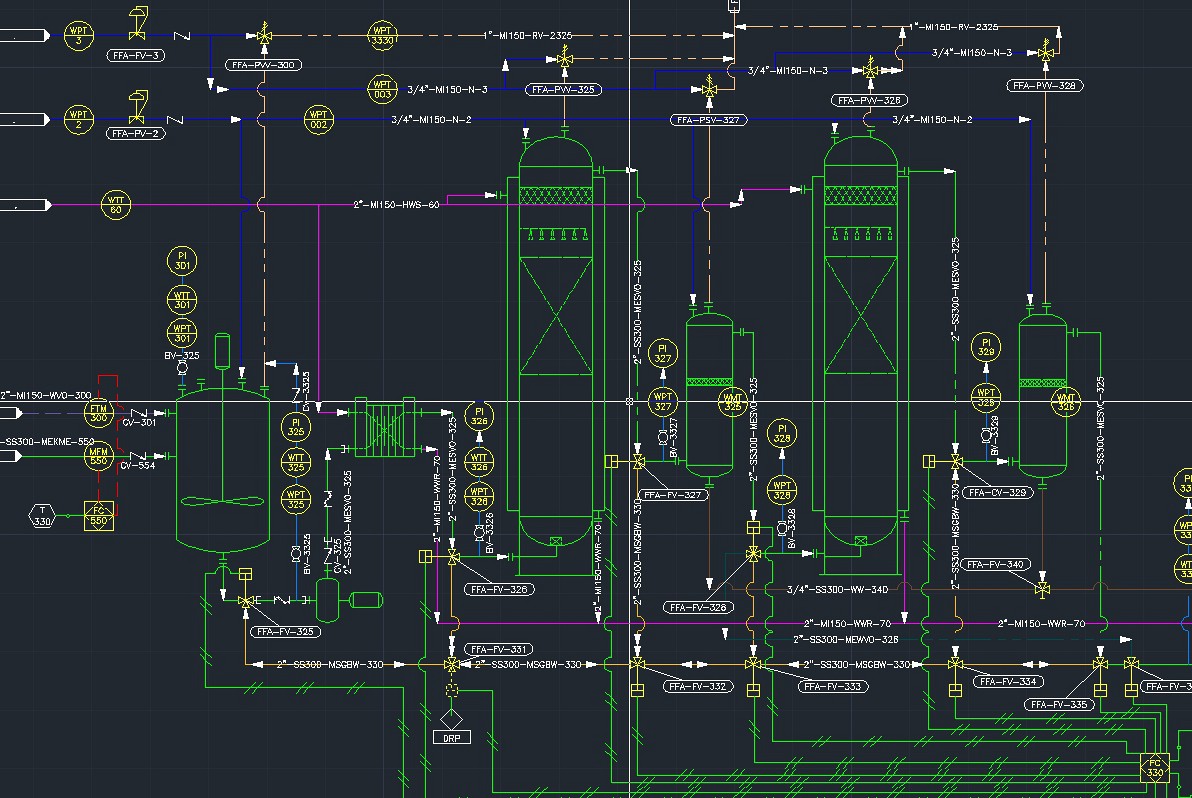

The P&ID is based on the process flow diagram and depicts the technical realization of a process by means of graphical symbols representing equipment and piping, together with graphical symbols for process measurement and control functions

Process Industry Practices (PIP)

PIP PIC001: Piping and Instrumentation Diagram Documentation Criteria

3. Definitions

Piping and Instrumentation Diagram (P&ID): Detailed graphical representation of a process including the hardware and software (i.e., piping, equipment, and instrumentation) necessary to design, construct and operate the facility. Common synonyms for P&IDs include Engineering Flow Diagrams (EFDs), Utility Flow Diagrams (UFDs), and Mechanical Flow Diagrams (MFDs)

Figure 1: Some of PIP members

South Australian Water Corporation (SA Water)

Technical Standard TS 112: Process and Instrumentation Diagrams (P&ID)

2 Scope

This Technical Standard (TS) shall apply to all the Process / Piping and Instrumentation Diagrams (P&IDs) produced for or by SA Water, and for all SA Water projects.

SA Water requires P&IDs to be prepared at the Concept Design stage for all plant and systems that include operable elements or instrumentation. Operable elements include manual, actuated, and automatic operation. P&IDs may be prepared prior to the Concept Design stage as appropriate. P&IDs shall be revised for each subsequent phase of the project or works.

ENGINEERS USE STANDARD TO DO DESIGN

At this point, you can still disagree that P&ID refers to Piping and Instrumentation Diagram. However, observe that the argumentation shown above is based on standards and technical documentation, it is not based on guessing. You can do the same and find reliable sources to basis your preference for Process and Instrumentation Diagram.

MY POINT OF VIEW

In my point of view, I agree about Piping and Instrumentation Diagram because we do not built industrial plants without piping info in the P&ID, I mean, where pipe designer will take information about pipe size and manual valves size and types?

Piping info is essential to process engineer perform fluid velocity and verify Hazard (backflow prevention for instance) and so on. In the other hand, If someone wants to understand the process, not only the sequence, only the PFD can give to this person the answer.

A P&ID without piping, most likely you will not be able to identify the fluid, class rating, if it is gas or liquid because it is part of pipe numbering. For those reasons and other I agree with Piping and Instrumentation Diagram.

In addition, a P&ID that do not has pipe and fitting info, in my point of view, is worst than a PFD because I will not be able to know any process info.

I first learnt about P&ID in portuguese as “Fluxograma de Engenharia” (Engineering Drawing), I was introduced to P&ID later on in a American Company. Although It was called Process and Instrumentation Diagram there, as per consideration above, for me Piping fits better to P&ID.

LAST WORDS

This article has no intention of pointing out who is wrong or right about P&ID. In the end, it doesn’t matter if you call P&ID as Piping or Process. Chemical process engineers will be able to understand the process, Piping engineers will continue to look for pipe and fitting for isometrics development, automation engineer will keep looking for control info etc because P&ID is a multidisciplinary document. What I really wish with this article is that you should take care to always develop your plant design based on the standards and procedures that apply to your project, that way, you will not have any issue with regulation or assessments.

INPROCESS BOOSTER P&ID – LEARN HOW TO READ AND DEVELOP P&ID TODAY

FREE MENTORING FOR CHEMICAL PROCESS ENGINEERS

If you are interested in improving your chemical process engineering skills take a look at my INProcess mentoring channel at

www.jefersoncosta.com/inprocess

Take a look also in my YouTube Channel The Chemical Process Engineer and Plant Design.

3 Comments