A common question many people ask me is what are the differences between Aspen Plus and Aspen HYSYS? Is Aspen the same as HYSYS? Which simulation software is better – Aspen Plus or Aspen HYSYS?

To start with, both software are proprietary from Aspen Technology Inc (A.K.A Aspentech). According to Aspentech Aspen Plus is the Leading Process Simulation Software in the Chemical Industry, while Aspen Hysys is the Industry’s #1 Process Simulation Software. Both of them claim to be applicable for bulk chemicals, downstream, Engineering, Procurement & Construction, midstream & LNG, upstream etc. However, as I started recording Aspen Plus training for my students (link below) some differences between Aspen and HYSYS have gotten more evident to me.

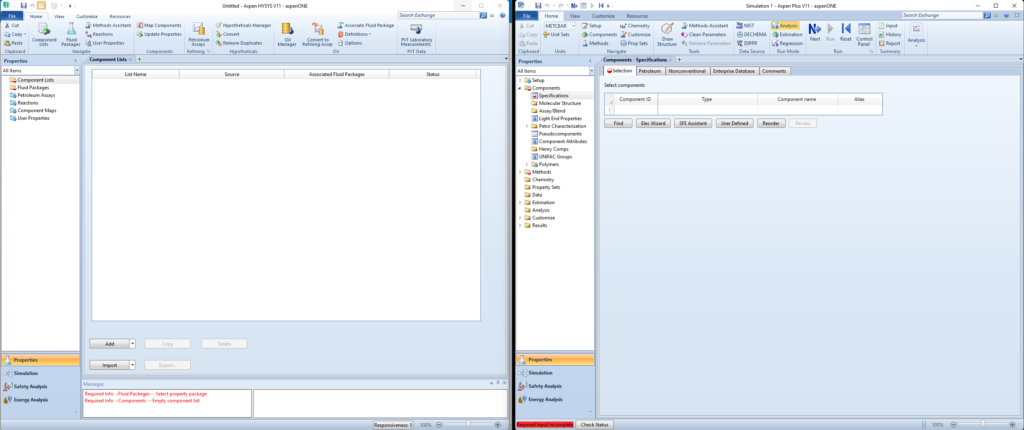

Their interface is very similar but not the same. As you can see above at the left side (Aspen HYSYS V11 new simulation) and on the right side (Aspen Plus V11 new simulation).

3 FEATURES ASPEN PLUS HAS, ASPEN HYSYS DOESN’T

Although Aspen Plus and Aspen Hysys can be used for same application in many industries, when you start a new simulation you can identify that Aspen Plus fits better for for fine chemistry, or all other nonpetro processes, such as acids, pharma, etc, while Aspen Hysys has more features related to for petrochemical/petroleum/downstream operations such as natural gas, liquified gases, fractionation of crude oil, characterization of petroleums, etc.

Now, I will list 3 main features you find in Aspen Plus but will not get in Aspen HYSYS.

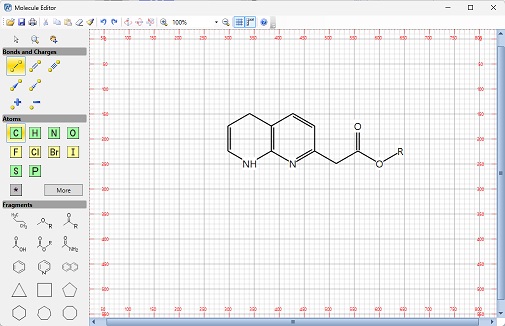

1) STRUCTURE FORMULA

There are many ways of adding components in Aspen Plus and Aspen HYSYS. The addition of pure components, hypothetical components and oil assay is available in both of them. However, only in Aspen Plus you will be able to add components based on a structural formula. This feature can be very helpful, especially for people in research and development.

Molecule Editor on Aspen Plus

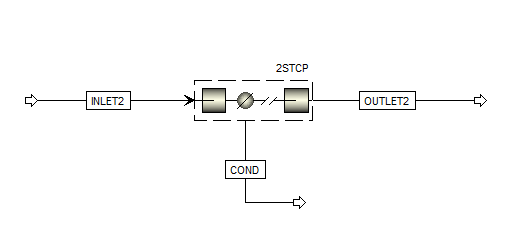

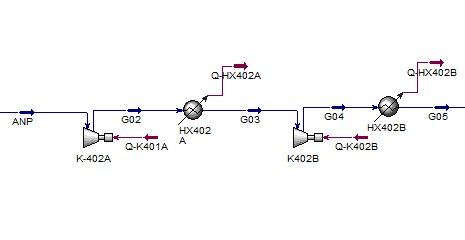

2) MULTISTAGE COMPRESSOR (IN JUST ONE BLOCK)

Compressors are one of the most used equipment in the chemical, petrochemical, oil&gas industry.

Multi-stage compressors use multiple stages of compression to delivery higher pressures than are possible with a single-stage compressor. These workhorses in the air compressor industry may be two-stage compressors or even three-stage compressors. However, for gas processing, a compressor can achieve more than 3 stages of compression. Below you can see a process flow diagram for a 4-stage compressor (multistage compressor).

Picure source: MOGAS

As a compressor is a compressor independent of its final pressure head (blower, booster, compressor, multistage compressor), in Aspen Hysys you will need to add as many compressor block/object as needed to represent each stage of compression although in real life it is delivered as a single equipment. This way, simulating a 2-stage compressor will lead to much more time in Aspen HYSYS as besides 2 compressor blocks, the process engineer will need to add also lines, coolers and vessel separators. In Aspen Plus you can solve it with just one block and inlet and outlet lines.

Multistage compressor block MCompr on Aspen Plus

Multistage compressor on Aspen Hysys

3) BATCH PROCESS

A batch process is one in which a series of operations are carried out over a period of time on a separate, identifiable item or parcel of material. It is different from a continuous process, during which all operations occur at the same time and the material being processed is not divided into identifiable portions (Handbook of Batch Process Design).

As softwares are built based on equations, you should not use steady state software to perform batch calculation just because batch equations are not the same as steady state equations. For the sake of many, Aspen Plus is able to simulate batch Reactors and Columns. But you do not have this option available in Aspen HYSYS.

Aspen Plus General-purpose batch operation block (left) / Rigorous batch distillation (right)

RBatch rigorously models batch or semi-batch reactors.

Above, you have seen 3 main differences between Aspen Plus and Aspen Hysys. You will learn much more details about each software once you start using them. Stay alert many companies require process simulation software expertise in chemical process engineering jobs. If you need to get skilled today in Aspen Plus, click on this link (GET SKILLED IN ASPEN PLUS)

Keep following my social media to learn more about chemical process engineering and plant design.

Regards,

Jeferson Costa