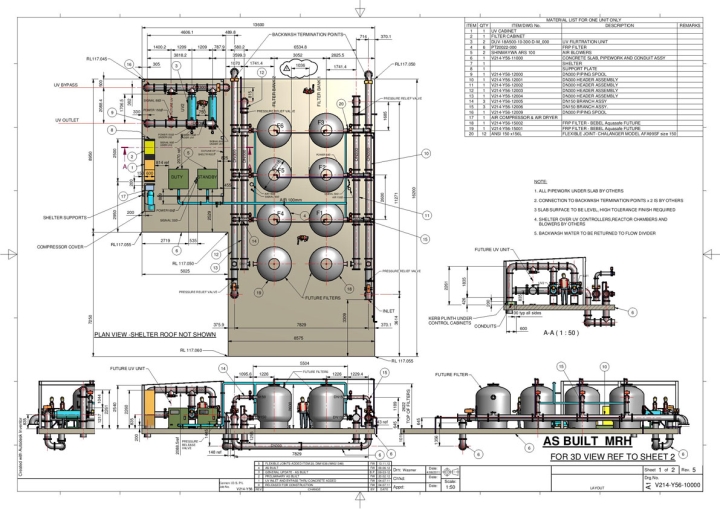

During the initial phase of a project, you will develop or be involved with at least three documents; process flow diagram (PFD), piping and instrumentation diagram (P&ID) and Plant Layout.

Process Flow Diagram is a deliverable developed by the chemical process engineer. It is the representation of heat and material balance in a drawing. It will give the inputs for most of the specifications developed during plant design.

The piping and instrumentation diagram will make possible the development of the system where the heat and material balance takes place. Its main purpose is to address piping, instruments, equipment, control etc to the design team. Industrial plants, generally speaking, are built based on P&ID.

However, PFD and P&ID are schematics. Only with these drawings, you are not able to tell the location of equipment, how far is one from another, or how many lengths of pipe are necessary to link systems for instance.

A set of documents is based on plant layout. Depending on its purpose, you may have a general arrangement, equipment location, equipment arrangement, plant of instruments etc. Any discipline that needs to consider the distance from a point to another needs to have a clear view of the plant layout. For example, the piping designer in the development of isometric, electrical designer in the development of cable rote and the chemical process engineer in the development of hydraulic calculation.

The chemical process engineer must know and understand plant layout in order to be able to perform calculations accordingly and address that to PFD and P&ID.

If during the later stage of design a battery limit is changed to another place, a new pipe size may be required to keep the same minimum pressure per customer requirements. If one equipment location changes, a pump or a compressor would be required to allow fluid flow, or its head should be increased or can be decreased.

Stay alert to plant #layout during the development of your engineering deliverables and avoid mismatching and rework.

To know more about my INProcess mentoring channel access https://www.jefersoncosta.com/inprocess

Drawing from Cannon Industrial Services Pty Ltd

(http://www.cannondesign.com.au/)