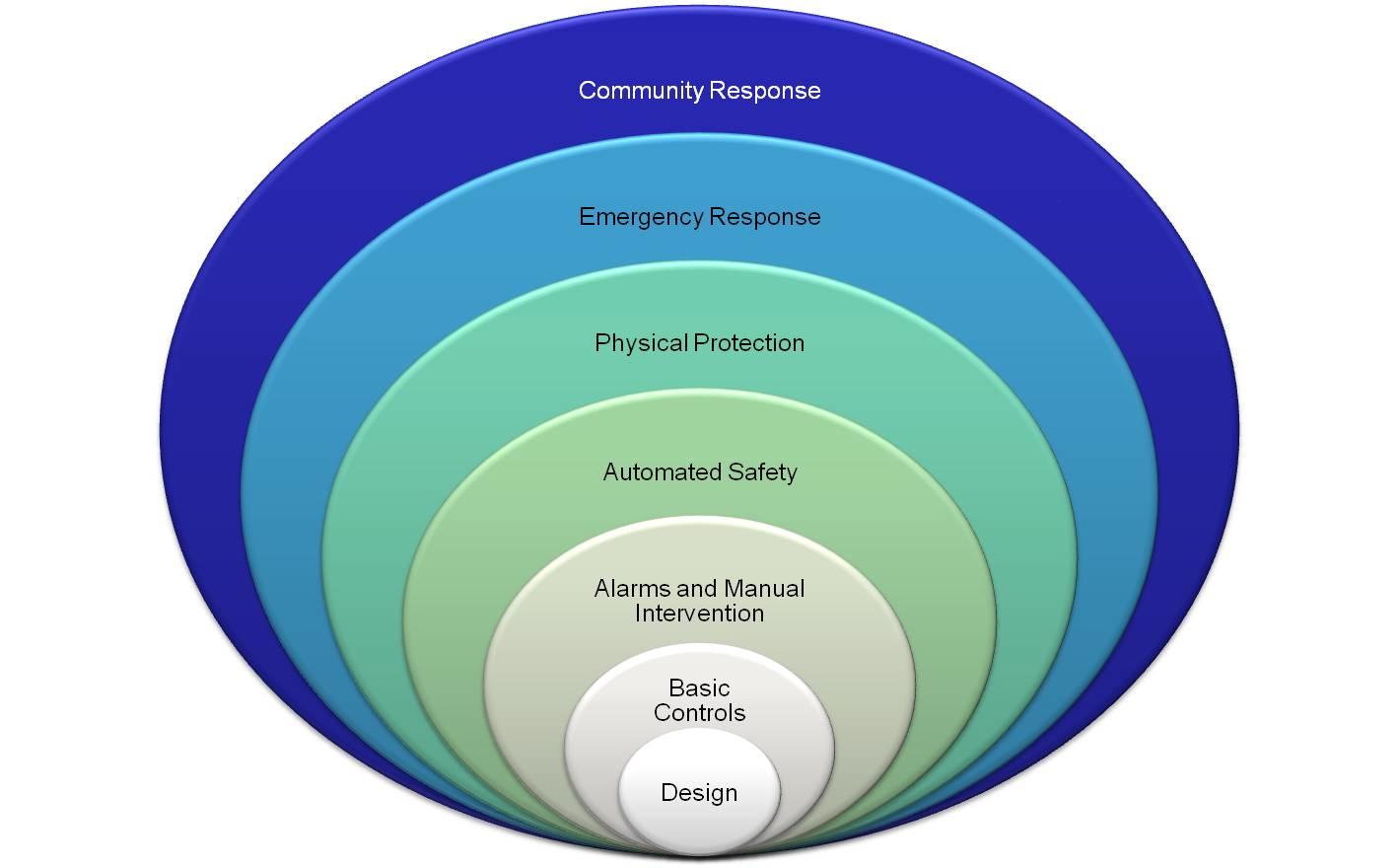

Chemical Process Engineer must understand how important is to have a safety culture. Hazard and Operability (HAZOP) is one of the most used qualitative methods related to process hazard analysis. Its main objective is to identify the causes of deviations from the design function, determine all major hazards and operability problem associated with deviations,...

CONTINUE READINGCooling Water Systems

Cooling water systems are responsible for taking out energy from the process. They are very important and can impact production. There are some types of cooling water systems, in the Cooling Tower (CT) type air is used to decrease water temperature. As Chemical Process Engineer you need to give some info to the Supplier,...

CONTINUE READINGProcess Safety Overview

Chemical Process Engineer deals with the conversion of raw materials into products using physical process, chemical reaction or both of them. As Process Engineer you SHALL need to understand each hazard you have in your process. It does not matter if you work supporting Operations or in a Project Office we are responsible to...

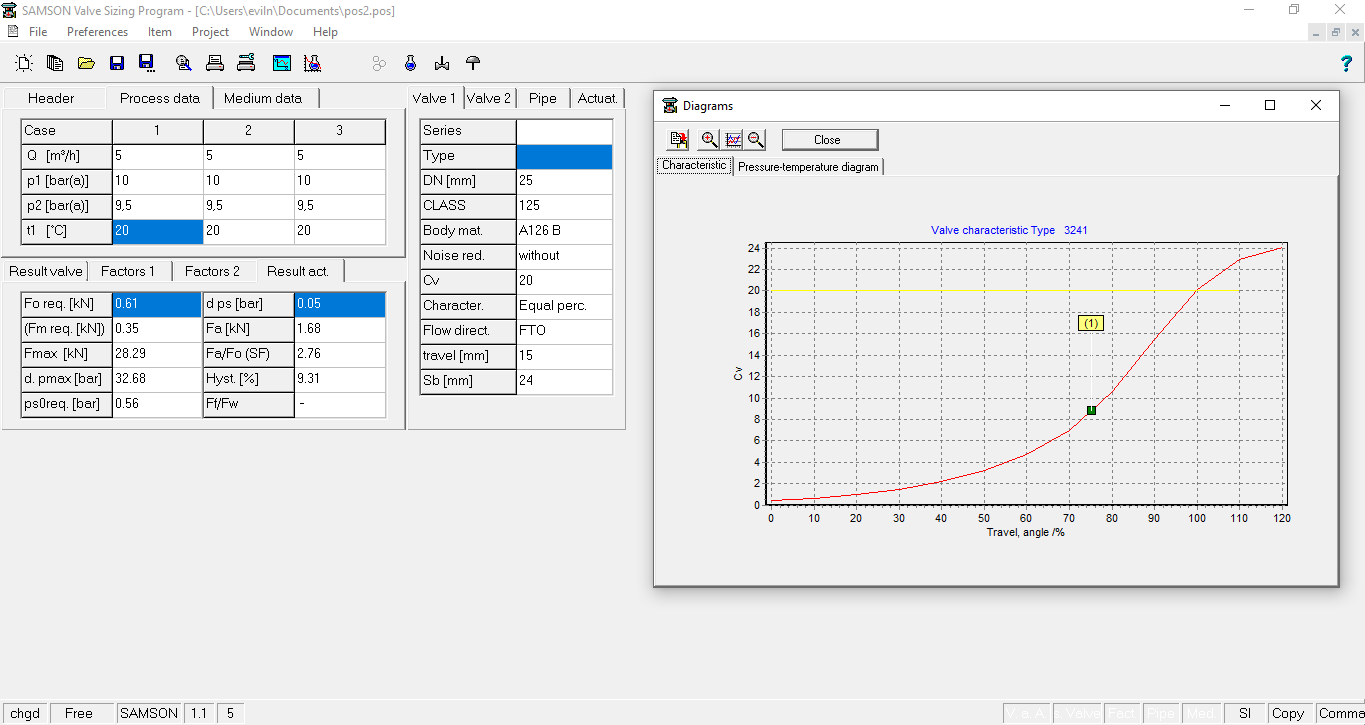

CONTINUE READINGFirst Step in Control Valve Design

As Chemical Process Engineer you need to be familiar with control valves function and design. To develop a process design you need to know which process data needs to be informed to Instrumentation Engineer or in other cases directly to Instrumentation Designer. Required process data depends on the kind of service is required by...

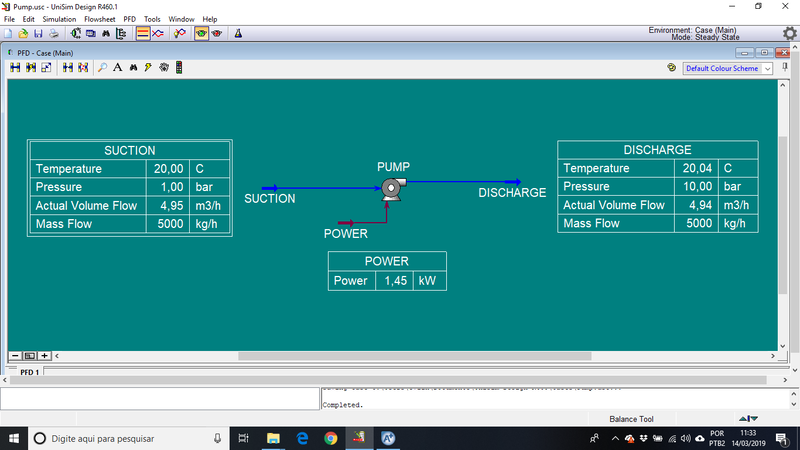

CONTINUE READINGProcess Simulation Software

Process Simulation software is tools developed to faster chemical engineering calculation. There are many of them in the market: Aspen Plus, Hysys, Unisim, ChemCad, Prosim, SimCentral, DWSim are some of them. Although they use the same basic engineering concepts their interface can vary a lot one from another and learn new tools may be...

CONTINUE READINGList of Documents

A great amount of documents is developed during process design. Some of them are specific for project phase others will be part of plant operations and subject to periodic assessment. Document List is where all documents related to a plant or a project are identified. To clarify, any document has it’s on identification usually...

CONTINUE READINGProcess Engineering Drawings

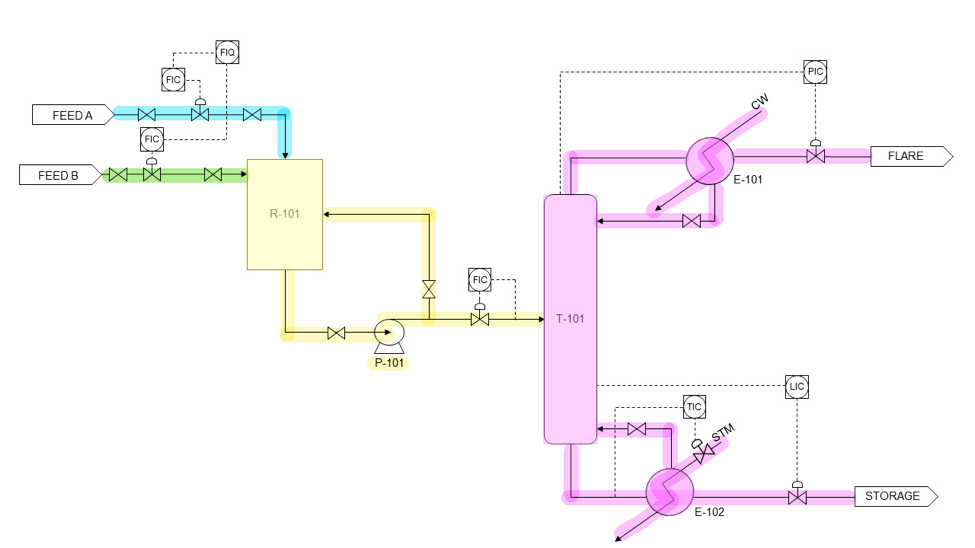

Let’s talk about process engineering drawings: Block Flow Diagram (BFD), Process Flow Diagram (PFD) and Piping/Process and Instrumentation Diagram (P&ID). Block Flow Diagram BFD is used in the early stage of a project. It can be drawn with boxes and there is no need for details. The main purpose of this drawing is to...

CONTINUE READINGChemical Process Engineer at Process Design

Chemical Engineering opens a wide range of opportunities. But the most fascinating of them, in my point of view, is Industrial Design. Be able to see conceptual to design, design to construction and construction to operation is something that few engineer has the opportunity to do. Supporting a process engineering team in the Detailing...

CONTINUE READING