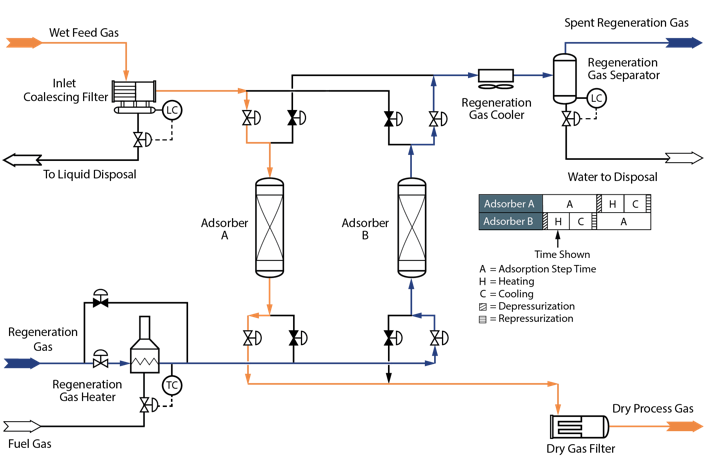

Although there are some methods available to remove water from a natural gas application, in a pre-selection we decided to use desiccant dehydration with regeneration process. As a chemical process engineer you need to inform supplier the feed gas specification (composition, pressure, temperature and flow) and the treated gas specification, for instance, gas dew...

CONTINUE READINGFacility Sitting Study

Facility Siting Study: What a Chemical Process Engineer should know about? During plant layout evaluation it is important to identify and consider all potential exposures that may affect the location of a new process unit and the impact that it will have around. hashtag#Facility siting study is related to process hazard analysis (PHA) and...

CONTINUE READINGHot Tapping, what is this?

Today let´s talk about hot tapping. Hot Tapping is the ability to safely tie into a pressurized system, by drilling or cutting, while it is on stream and under pressure. Hot tapping is used in order to repair areas that have undergone mechanical damage or corrosion or to add branches for system modifications. Be...

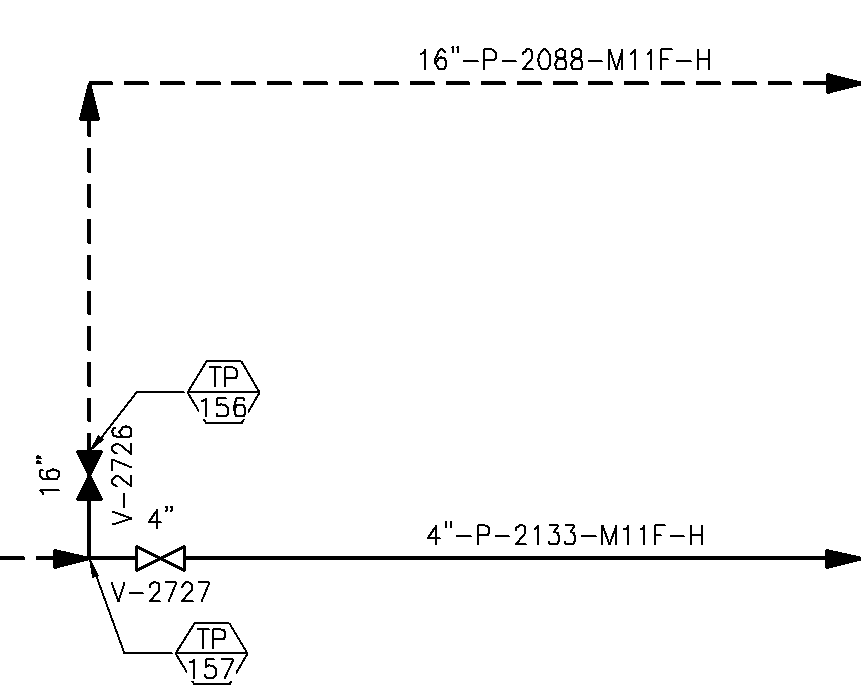

CONTINUE READINGTie In Point

Have you ever heard about Tie-in Point? It is a wide and important subject to process design that I learned only after College. In a few words, the tie-in point is a future connection to an existing process. That means that exists an industrial plant in operation and to “add” a new process it is...

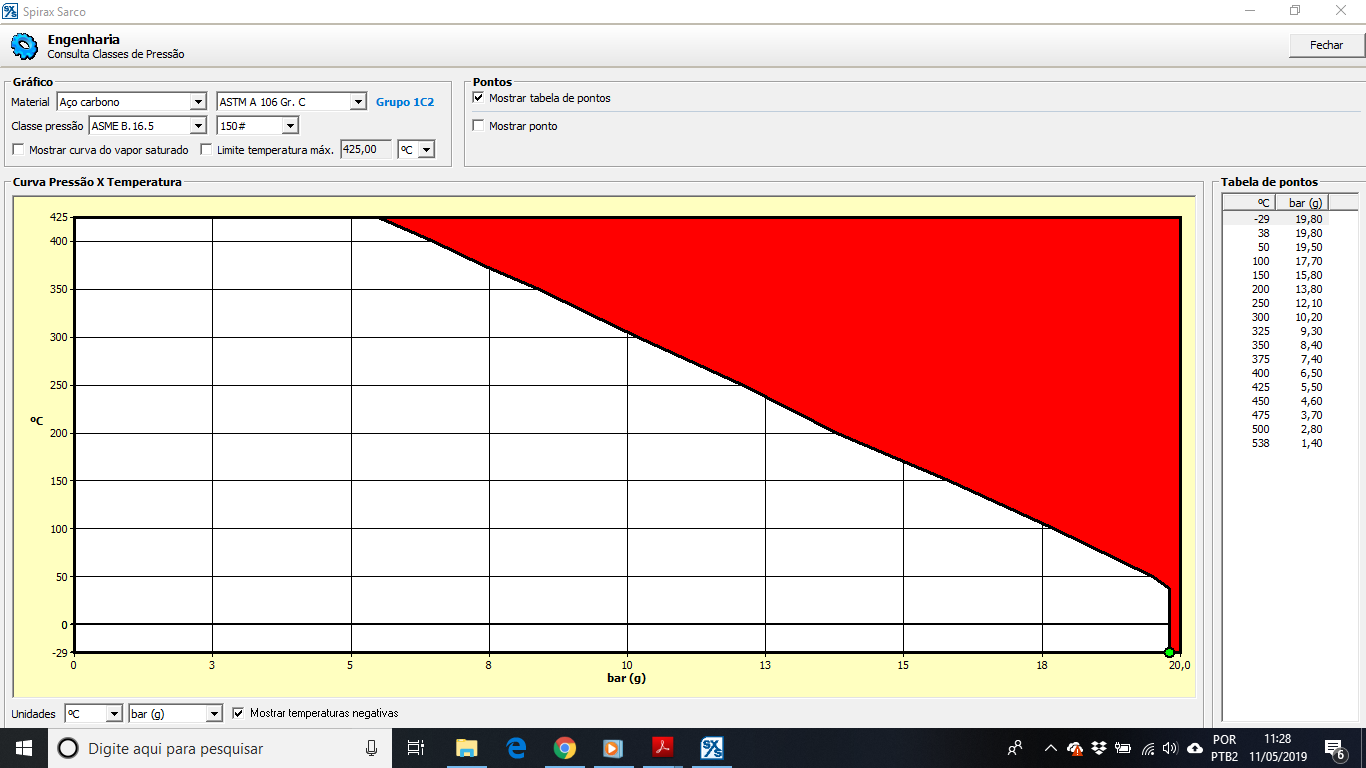

CONTINUE READINGPressure Class

As a process chemical process you should know that piping class refers to valves, flanges, fittings and gaskets (ASME B16) and not to the pipe pressure rating. Pressure rating is a relationship between temperature and pressure for standardized components mentioned above. This tells us what is the maximum allowed working pressure (MAWP), for a...

CONTINUE READINGProcess Piping

Process piping is probably something that every Chemical Process Engineer will always deal with. In a new project, you need to design the pipe size that best fit the process. In existing plant you need to evaluate if the piping system is not bottlenecking the process. From pipe size you calculate fluid velocity and...

CONTINUE READINGStay Alert About Job Offering on LinkedIn

Some colleagues and connections have asked me about some suspicious job advertisements. I hope this post help people to avoid this kind of situation. Linkedin is a great tool for finding a job opportunity and I personally already was invited and/or applied for some job openings. In none of them, I was asked to...

CONTINUE READINGCommissioning and Startup Tips

In my years as Chemical Process Engineer, I worked not only in the office but also in the field doing commissioning, startup and plant troubleshooting. I really like the office but field activities are very rewarding. In my point of view: 1) Commissioning and startup increase process engineer technical skills. You really get the lesson...

CONTINUE READINGHazard and Operability Study (HazOp)

Chemical Process Engineer must understand how important is to have a safety culture. Hazard and Operability (HAZOP) is one of the most used qualitative methods related to process hazard analysis. Its main objective is to identify the causes of deviations from the design function, determine all major hazards and operability problem associated with deviations,...

CONTINUE READINGCooling Water Systems

Cooling water systems are responsible for taking out energy from the process. They are very important and can impact production. There are some types of cooling water systems, in the Cooling Tower (CT) type air is used to decrease water temperature. As Chemical Process Engineer you need to give some info to the Supplier,...

CONTINUE READING